1. Introduction

The innovation of steam engine back in the late 19 the century resulted in an enormous growth of industrial activities globally, which in turn resulted in an increase deterioration of the ecosystem because of the discharge of highly polluted effluents in the forms of solid, liquid, and gas. The efforts have been put forward toward developing eco-friendly and sustainable processes in order to avoid rapid degradation of the ecosystem. In the fields of mineral processing and extraction of metals joint efforts are put forward to developing environmentally friendly processes [1]. Owing to the gradual depletion of high-grade ores, attention are now being focused toward recovering metal from ores, complex and lean ores, which cannot economically be treated by conventional routes [2,3]. Bio-hydrometallurgy is a new concept that involves the use of various microorganisms to recover metals from their ores. It is also environmentally friendly unlike conventional hydro-metallurgical process [4]. Bio-hydrometallurgy technique applies to different types of materials, so far unusable resources, by which metals can be recovered and also generates minimum effluents and therefore is preferred as green technology. For last several decades bioleaching prioritize in application for metal recovery from ores/ concentrates namely; pyrite arsenopyrite, chalcopyrite, calcite [5]. Among the major bacteria group that are promising in bioleaching process are chemolithotrophic acidophiles namely, Acidithiobacillus ferrooxidans, Acidithiobacillus thiooxidans, and Leptospirillum ferrooxidans and heterotrophs like Sulfolobus. Some of eukaryotic bioleaching microorganisms that applied in metal recovery include fungal species such as Aspergillus niger and Penicillium from industrial wastes [6]. The recovery of free milling gold by gravity and direct cyanidation proved to be straightforward and well established, refractory ores pose a very different challenge to producers. The first challenge is determining the reason for the poor recovery by direct cyanidation, which can be caused by one or more contributors. The oldest and best understood is gold locked in sulphide, and most frequently pyrite. The second contributor to refractory behaviour is arsenic, which causes high refractoriness even at low concentrations. The presence of carbon in the ore is also a frequent cause of poor recovery. In this paper, gold ore sample (with FeS2 and FeAsS as the main sulfides) from Tianli gold mine, Liaoning province, China was treated in four different media.

2. Materials and Methods

2.1 Mineral samples preparation

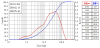

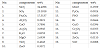

The sample ore for this study was obtained from Tianli gold mine, China. Chemical analysis of the representative sample by AAS (atomic absorption spectroscopy) was conducted. The sample Ore was sieved to -0.075 mm before used for all leaching experiments. X-ray diffraction analysis of the sample showed pyrite (FeS2) as the major phase and Chemical analyses also indicated that the sample contained arsenical pyrite or arsenopyrite (FeAsS). The particle size of the sample was 80% below 75 μm (Figure 1). X-ray fluorescence spectroscopic analysis of the sample was conducted and the result is shown in table 1.

2.2 Harvest of culture medium

A mixed culture medium (HQ 2011) was used, the studies, which utilized ferrous ion or elemental sulphur as energy source. Cultivated by Northeastern University and mainly contain Acidithiobacillus ferrooxidans, Ferroplasma acidiphilum, Leptospirillum ferriphilum etc. The cells were incubated at 180 rpm and 37°C in sterile 9K basic salt medium containing different energy substrates [7] After incubation for three days, some portion of the cells was harvested by centrifugation at 10,000 rpm for 10 min.

2.3 Bioleaching experiments

The experiments were conducted in 500mL conical flasks containing 200mL of four different media, mix bacterial medium, mix centrifuged bacterial culture medium, in acidic medium and in a sterile medium. The pulp density was 3%. Sample of the ore mineral was added into media without Fe2+,[9] added with culture medium (inoculated amount of 10%), and pH was adjusted to 1.6 with H2SO4 and then placed into a constant-temperature incubator (175 r/p) for days.

2.4 Chemical analysis

Measurements of pH and potential were performed every day. Samples were aseptically withdrawn from the flasks every two to three days for chemical analysis. The samples were separated by centrifugation at 5000 rpm for 10 min. the dissolve Arsenic and total iron and were measured.

3. Results and Discussion

3.1 pH

At 37°C, 10% Inoculum, 175 r/p, 3% pulp density and 36 days the leaching time. The effect of pH on the sample ore bio-oxidation was studied. The results are presented in Figure 3. The pH of the centrifuge and mixed bacterial media during the dissolution of the sample showed almost similar characteristics. Within the first 3 day of the experiment, the percentage of the total Fe ion were 86% and 87 for the sample with mixed and centrifuge bacterial culture medium (Figure 4), this clearly indicates that the oxidation rate of the sample is higher at the initial stage, so the increase in pH is apparent. Furthermore, the increase in concentration of total iron (the Fe3+ ion) which partake in the oxidation process resulted in the subsequent decrease of pH (eq. (1)), [8] to nearly 1.1 on the 36th day. On the other hand the percentage of the dissolved total Fe ion in acidic and pure sterile media were 16% and 15% respectively, indicating that the oxidation rate is lower in the initial stage. It is believed that the decrease in the pH resulted from the dissolution of pyrite being net acid releasing sulfide and arsenopyrite presents in the ore sample.

3.2 Oxidation potential

The variations in the redox potential (Eh) with time is given in Figure 5. It can be seen that after the first day, the redox potential of the samples with mix and centrifuge bacterial medium were increased reaching the values of about 640 and 465 mV after 3 day of the experiment. On the sixth day the redox potential of the sample with mix bacterial medium reached its peak value (680 mV) which indicates that microorganisms of the mix culture medium were more active at pH of about 1.5 to 1.6, whereas that of the centrifuge bacterial medium reached it maximum value (650 mV) on the 18th day of the experiment. The higher dissolution of arsenic and total Fe could be attributed to the higher redox potential of the solution. On the other hand the oxidation potentials of pure sterile and acidic media were 310mV and 340mV indicating that the dissolution of the sulphide was much lower.

3.3 Percentages of dissolved arsenic and total Fe

It was observed that the dissolution of the arsenic and total iron for the sample with mix and centrifuge bacterial medium increases with the gradual decrease in the pH, initially the dissolution of arsenic were 73% and 34% (Figure 6) and the dissolved total Fe (Figure 4) were 87% and 86% within the first three day of the experiment and continue to rise during the process reaching up 99% both while the dissolution of the arsenic for the sample in acidic and pure sterile medium were 28% and 18% whereas those of the total Fe were 16% and 15% within the first three day of the experiment which appear to be low at the initial pH. The oxidation potential of the sample with mix bacterial and centrifuge bacterial medium is low but continue to rise during the whole process, which indicates that the bacteria are difficult to survive at the pH of 2 or above though could be alive but less active [8].

4. Conclusion

The bio-oxidation of arsenic-bearing gold ore from tianli gold mine was investigated by comparing the dissolution of the sample ore in four different media, in a mix bacterial medium, mix bacterial medium after centrifugation, acidic medium and in a pure sterile medium. The experimental results showed typical oxidation characteristics for the four different media. After the first day, the redox potential of the samples with mix and centrifuge bacterial medium were increased, reaching the values of about 640 and 465mV after 3 day of the experiment. On the sixth day the redox potential of the sample with mix bacterial medium reached its peak value (680 mV) which indicates that microorganisms of the mix culture medium were more active at pH of about 1.5 to 1.6, whereas that of the centrifuge bacterial medium reached it maximum value (650 mV) on the 18th day of the experiment. The higher dissolution of arsenic and total Fe could be attributed to the higher redox potential of the solution. On the other hand the oxidation potentials of pure sterile and acidic media were 310mV and 340mV indicating that the dissolution of the sulphide was much lower. It is believed that the decrease in the pH resulted from the dissolution of pyrite being net acid releasing sulfide.

Competing Interests

The authors declare that they have no competing interests.