1. Introduction

Environmental pollution caused by petroleum hydrocarbon such as heavy oil, diesel fuel, gasoline, engine oil and mineral oil are widespread due to improper disposal [1]. Industrialization and accidentals spills of petroleum and petroleum products occur regularly during the exploration, production, refining transport and storage [2]. Oil sludge is defined as scheduled waste in Malaysia Environmental Quality (Scheduled Wastes) Regulations 2005 has been classified by the United State Environmental Protection Agency (USEPA) as a hazardous organic complex. The improper disposal of these components into the environment could endanger and destroyed of local system in animals and plant tissues that may lead to death or mutations. Therefore, the presence of these chemical in the environment poses serious risk to human health and ecosystem [3]. Biological degradation also known as bioremediation is one of the effective method for the removal of petroleum hydrocarbon in soil [4]. There are different treatment technologies under bioremediation such as biostimulation, bioventing, bioaugmentation, biofilters, bioreactors composting and landfarming [5]. Biaoaugmentation is one of the selective techniques used in bioremediation to enhance the microbial population by adding selected microbial cultures in contaminated site degrade contaminant and reduce clean up time and cost [6-9]. This method is known to improve the biodegradative capacities of contaminated sites by speed up the rate of degradation of a contaminant. In this project, it was proposed to implement in-situ bioremediation in a bioreactor by the process of continuous aeration using three tubing connected to air pump (Model Resun LP100 Low Noise Air Pump). Unlike simple venting, the objective of continuous aeration (ASP) was to remove petroleum hydrocarbon contamination by providing oxygen to the microbes (LIBeM) thus accelerating aerobic bioremediation in the soil. Therefore the aim of this study is to evaluate the aerated static pile (ASP) - enhanced bioaugmentation of oil sludge by locally isolated beneficial microorganisms (LIBeM) using different delivery techniques in high concentration laboratory scaleup as a green technology treatment (landfarming) of hydrocarbon contaminated soil.

2. Materials & Methods

2.1 Invention of Aerated Static Pile (ASP)-Bioreactor System Design

The aerated static pile (ASP) - bioreactor system made up of acrylic material with dimension of 60 cm x 40 cm x 20 cm (length x width x height). This ASP-bioreactor invention has two main components namely: 1. 3 tubing running parallel for aeration as the ASP unit within the sand and gravel layer and, 2. the pump (Model RESUN LP100 Low Noise Air Pump) to supply oxygen continuously the system. An input for feeding aeration to the soil is supplied with three silicone tubing’s at the side of the ASP-bioreactor that connected to air pump. The ASP - bioreactor is divided into 3 parts where the base is filled with gravel-sized (1-1.5cm) followed by sand and the soil on the top surface as treatment zone. The rational of this arrangement is as depicted in the actual field scale. Figure 1 showed the schematic design of aerated static pile (ASP)-bioreactor system.

2.2 Soil preparation

Soils used in this study were obtained from THN Landscape Supplies Nursery. 2 kg of soil were sieved through 0.20 mm sieve size. The soil samples were filled in each ASP-bioreactor system for further bioremediation studies (Sharma & Rehman, 2009) [10].

2.3 Sources of microorganisms

The cultures were obtained from Environmental Microbiology Laboratory, Faculty of Science & Natural Resources, Universiti Malaysia Sabah. These microorganisms have been proven to degrade oil and phenol based on the previous research done by [11,12]. These three selected consortia formulation also has been proven to be the best oil sludge degraders as reported by [13] (Figure 2).

2.4 Inoculum preparation of LIBeM

LIBeM consortia consists of (C. tropicalis-RETL-Cr1+ C. violaceum-MAB-Cr1 + P. aeruginosa - BAS-Cr1 ) was cultured to 1.5 liter Ramsay broth in 2 liters Erlenmeyer flasks with 2 mM of MgSO4.7H2O and 20% (v/v) of oil sludge were added as a carbon sources. The flasks were incubated in an orbital shaker agitated at 200 rpm for 30°C within 24 hours. After incubation, the OD was assessed by using spectrophotometer (Model CECIL CE 1011) set at 600nm and a total of 1.0 liters of inoculation was sprayed into the soil for bioremediation studies.

2.5 Protective agent of LIBeM

The protective agents used in this study were skimmed milk brand (R & M Chemicals) as a source of Ca2+. It contains 1.5% of milk fat with natural milk powder and highly nutritious for microbiological used. For microbial formulation of powder, 30% freshly skim milk were dissolved in 1 liter of sterile distilled water as requirement of each experiment. The selection of this protective agent was based on the preliminary study by Lim et al., [14] with some modification.

2.6 Preparation of microbial formulation LIBeM powder (LIBeMPOW) by freeze drying

The microbial formulations of LIBeM powder were done by harvesting the cells at the early stage of stationary phase under aseptic condition by centrifugation for 10 mins at 12,857x g (Eppendorf, Centrifuge 5810R). 100 mL harvested cell were washed twice using 0.02 M phosphate buffer at pH 7.2. The cell pellets were then resuspended in the same volume of skim milk (30%) as protective agent. Each suspension (20 mL) was transferred into a sterile universal bottle and chilled at 4°C for 2 hours. The chilled suspension was frozen under freezing condition at -800C for 24 hours. The LIBeM formulation in powder form was prepared using lyophilization or freeze method drying under vacuum condition using freeze dryer 6L Model LABCONCO.

2.7 Preparation of microbial formulation LIBeM capsule (LIBeMCAP)

For preparation of LIBeM formulation in capsule form, the LIBeM powder were encapsulated in hard gelatin capsule with high premium capsule sheath. 0.5 g of LIBeM powder was filling in double locking capsules. These LIBeM capsules are stored in 4°C for further used in bioremediation process.

2.8 Experimental set-up

The effectiveness of microbial formulation LIBeM- LIQ, LIBeMPOW and LIBeM-CAP using to maintain viability of microbial strains was done by carrying out the biodegradation experiment in an ASP-bioreactor system with dimension of 60cm x 40cm x 20cm (Figure 3). The experiments (duplicates) for each ASP-bioreactor were carried out for 56 days at open and air ventilated with different delivery techniques as shown in Table 1.

2.9 Technical procedures protocol (TPP)

For each of the ASP-bioreactors experimental unit the soils were tillage daily and watering (0.4 liters) with distilled water at an interval 2 days to maintain the water holding capacity of soil. The inoculation of consortia LIBeM- LIQ (0.2 liters) into each plot was done for every 2 weeks during treatment periods. For treatment by LIBeM-POW and LIBeM-CAP a total of 5% (w/w) were pour into oil sludge contaminated soil for bioremediation studies. Initial readings were taken immediately after the inoculation of the bacterial culture and further. The soil samples were drawn after every 7th day from the respective experimental unit for prior analysis. The experiment (duplicates) was lasted in the ASP-bioreactors system until the total petroleum hydrocarbon (TPH) in the treatment soil drop to 3% as prescribed by Department of Environment (DOE), Malaysia for safe release to the environment. For natural attenuation treatment (control plot) the same technical procedures protocol were applied except inoculation of LIBeM into the soil. Oily sludge in the treatment zone of natural attenuation plots which were without inoculation of LIBeM.

2.10 Analysis of oil sludge contaminated soil

2.10.1 pH

Analysis pH was done as according to McKeague, [15]. 20 g of soil was weighed and mixed in a beaker contain 40 ml of distilled water. Analyses were done by taking three reading for accuracy using the pH meter.

2.10.2 Temperature

The temperature of each plot was measured by using thermometer in three different places at each bioreactor treatment. The reading was recorded and the average was obtained.

2.10.3 Soil moisture content

The soil moisture was analysed by using gravimetric method as mentioned by [15]. An empty crucible was weighed and record as M1. Then, 10 g of soil sample were grained with mortar and pestle and will be record as M2. The soil sample was dry at 110°C for 24 hours in an oven. Let the soil being cooled in desiccator and weighed the crucible as (M3). The soil moisture content was measured by using the formula (1).

M1 = Weight of empty crucible (g)

M2 = Wet of crucible + wet soil in (g)

M3 = Weight of crucible + dry soil in (g)

2.10.4 Microbial population

The growth of microorganism in each plot soil was determined according to method APHA 9215. Analysis was carried out weekly in each plot study. 10 g of soil sample was mixed with 100 ml sterile distilled water by diluting 1 mL of soil sample into 9 mL of sterile distilled water (dilution plate technique). The dilution series from 10-3 until 10-5 were chosen to calculate the biological population. 0.1 mL of culture was spread into Nutrient agar and will be incubated at 30°C for 24 hours. The total CFU was calculated based on the colony growth in the agar. The number of CFU/ml calculated by using formula (2).

2.10.5 Determination of total petroleum hydrocarbon (TPH)

Total petroleum hydrocarbon was carried out based on gravimetric method (Soxhlet extraction) (USEPA 3540C) [16]. 20 g of soil sample was grained and placed in thimble and were extracted with dichloromethane (DCM). Then the thimble was placed in Soxhlet extractor. 250 ml of dichloromethane were added into round bottomed flask (RBC). After that, the soxhlet extraction was arranged and mixed with enough dichloromethane until it covers the thimble. The cooling temperature and mantel heater was set at 17°C and 4°C respectively. The extraction process will takes places for less than 24 hours. Then the content was cooled and let the DCM flow to the round bottomed flask from the extractor. The total solvent will be cleared completely with the vacuum evaporator at 40-50°C. By using the rotary pump, let DCM left the sample. The RBC together with the extract was cooled in desiccator after being dried in oven at 400C. The RBC was measured until constant weighed obtained. The percentage of total petroleum hydrocarbon (TPH) was calculated using the formula (3).

2.10.6 Determination of carbon profile

The total petroleum hydrocarbon was extracted by soxhlet apparatus using dichloromethane as a solvent following the method of (USEPA 3540C). The degradation of petroleum hydrocarbon was determined by gas chromatography GCMS (Perkin Elmer).The purpose of chromatogram acquired from the analysis was to interpret the biodegradation profile of aliphatic hydrocarbon (n-alkane) and polycyclic aromatic hydrocarbon (PAHs). Column Elite 5MS (30 m x 0.25 mm x 0.25 μm) were used together with helium gas for hydrocarbon analysis. 1μL of sample was injected into GCMS at 35°C.

3. Results & Discussions

3.1 Biodegradation of oil sludge contaminated soil by consortia LIBeM using different delivery techniques

3.1.1 TPH reduction profile and biodegradation rate

The reduction of Total Petroleum Hydrocarbon (TPH) and biodegradation rate of consortia LIBeM-LIQ, LIBeM-POW and LIBeM-CAP in an ASP-bioreactor system for 20% v/v concentration levels versus time is presented in Figure 4 (a-d). On the contrary, natural attenuation (control treatment) which consisted of oil sludge contaminated soil with indigenous microorganisms was also analysed. The results showed that indigenous microorganisms (Natural attenuation) were able to degrade oil sludge in small TPH reduction of 51.1 g/kg at 20% v/v concentration levels studied.

By improving the soil with augmented consortia LIBeM (C. tropicalis +C. violaceum +P. aeruginosa), the results showed that rapid degradation of TPH was occurring in the first 14-28 days of incubation, and thereafter the biodegradation decreased gradually till the end of experiments. For the first 14 days of incubation, LIBeMLIQ showed the highest biodegradation rate with 5.84 g/kg followed by LIBeM-POW 4.34 g/kg, LIBeM-CAP 2.85 g/kg and NA with 1.87 g/kg respectively. This finding suggests that the rapid removal of TPH was actually occurred in the first 4 weeks which represents a further decomposition of the hydrocarbons (mainly saturated fractions) at the early stage of bioaugementation.

The results also demonstrated that the maximum biodegradation efficiency as recorded in descending order LIBeM-POW with 92%> LIBeM-CAP (86%) > LIBeM-LIQ (81%) > NA (26%). The comparison of TPH reductions using three delivery techniques is due to the reason where the different microbial formulations of LIBeM are resulted to different biodegradation efficiency. For LIBeM-POW, the powder structure is directly attached to the soil surface right after the inoculation was done. However LIBeM-CAP which contains hard gelatin capsule, this material has to be degraded first before the LIBeM directly distribute to the soil surface. As compared to LIBeMLIQ, bacteria-yeast survival rates on liquid formulations are decrease by times because this formulation does not provide a protective environmental for microorganisms and the number of bacteria distributed in soil are quite heterogeneous [17].

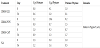

Interestingly, when inoculations of LIBeM-POW take place in contact with oil sludge, they immediately start to lock up and contain the spilled materials. In the presence of moisture content in soil, LIBeM-POW was activates and start to breaking down and digesting the oil. The strong binding between LIBeM-POW with oil sludge help LIBeM-POW to speed up the rate of biodegradation thus make it maximum removal of TPH with 183.3 g/kg. These strains start to utilized and consume oil sludge into nontoxic byproduct such as carbon, carbon dioxide and lipids. At the end, these by-products are used again as a source of energy to multiply. The combination of three strains C. tropicalis- RETL-Cr1 + C. violaceum -MAB-Cr1 + P. aeruginosa- BAS-Cr1 enhanced the biodegradation of oil sludge by attributing the multiple metabolic capacities and the synergetic effects between the association members, causing the increase of bioremediation efficiency. This consortium has showed excellent performances in degrading oil sludge as compared to other consortia LIBeM [13]. This finding is supported by Zhang [18], who found that synergistic effects were observed on the removal of total petroleum hydrocarbon and polycyclic aromatic hydrocarbons via the amendment of yeast-bacterial co-culture with a 48-day degradation of 56% for TPH and 32% for polycyclic aromatic hydrocarbons, respectively. He found that synergistic effect of yeast-bacteria was further evidenced by the increase of biomass and enzyme activities in soil [18]. Table 2 shows the summary of efficiency and rate of biodegradation at 20% (v/v) oil sludge by different delivery techniques after 56 days treatment period.

3.2 Biodegradation Profile of Oil Sludge Contaminated Soil by LIBeMLIQ, LIBeM-POW, LIBeM-CAP and Natural Attenuation (NA)

The initial and final biodegradation profile of oil sludge treated by LIBeM consortia by different delivery techniques was observed and determined using Gas Chromatography-Mass Spectrometer (GCMS) analysis. The peaks were clearly distinguishable and identified using alkane standard as presented in Figure 5. It can be observed that the first peak displayed at the retention time range 12.5 minutes.

Figure 5 (a, b) showed n-alkanes in the range of C12–C28 were found to be major compounds in the initial concentration of oil sludge at week zero. By observing the series of GC-profile, there was a significant change of the saturate fraction across the incubation period. This can be identified by comparing the degradation percentage of individual compound in the oil sludge.

The results also depicted a significant decrease of peaks in the beginning and in the end of the experiment. This indicated biodegradation reaction occurred throughout incubation period where carbon compounds was losing gradually, resulting in the decrease of the saturation fraction. This finding is in line with Simkovic et al., [19], who reported that the reduction of peak during was occurred during the last week of treatment illustrated that biodegradation was occurred rapidly during after the incubation periods. The profile also showed that, the low-molecular-weight alkanes may have undergone microbial degradation compared to the high molecular-weight alkanes.

3.3 Biodegradation Ratio of n-C17: Pristane, n-C18: Phytane and Pristane: Phytane by LIBeM-LIQ, LIBeM-POW and LIBeM-CAP and NA

The two isoprenoids compound pristane (C19H40) and phytane (C20H42) which commonly used as biomarkers for evaluating the biodegradation potential of oil sludge was conducted in this study. The pristane/phytane (Pr/Ph) ratio is one of the most commonly used geochemical parameters that has been used as an indicator of depositional environment with low specificity due to the interferences by thermal maturity and source inputs [20,21]. The early effect of microbial degradation can be monitored by the ratios of biodegradable to the less degradable compounds. The rate of degradation of these isoprenoids compounds compared to corresponding length n-alkanes provides useful insights into the extent of biodegradation and microbial activity in hydrocarbon rich sample [22].

The results on isoprenoids on n-C17 and n-C18 for LIBeM consortia are shown in Table 3. The analysis of n-C17: Pr and n-C18: Ph ratio for both treatment are shown in range 0.6- 10.6. It is clearly observed that, the n-C17: Pr is much lower than n-C18: Ph with 3 to 4 - fold lower in LIBeM-POW and LIBeM-CAP respectively. This finding is significant highlighted that the preferential biodegradation in pristane is much higher as compared to phytane.

As shown in Table 3 the value on n-C17: Pr and n-C18: Ph at the final day of 56 are lower than the initial day of the experiment. The lower the value obtained during the final experiment described the higher degradation of hydrocarbon fraction in the oil sludge. LIBeMPOW showed the reduction of n-C17: Pr and n-C18 with 0.3 and 9.9 while LIBeM-CAP demonstrated the reduction of 0.1 and 8 followed by LIBeM-LIQ with 0.2 and 3.1 respectively. Natural attenuation recorded the smaller degradation value of n-C17: Pr and n-C18 with 0.1 and 1.6 only. This mark the ratio of n-C17: Pr and n-C18 higher by 3-fold and 1.2-fold in LIBeM-POW. This result reveals that treatment by LIBeM-POW is well performed and synchronized with the high TPH reduction as discussed above.

3.4 Degradation of aliphatic hydrocarbon (n-alkanes) by LIBeM-LIQ, LIBeM-POW and LIBeM-CAP

The GC-MS analysis of oil sludge detected heptadecane (C17C36), octadecane (C18H38), nonadecane (C19H40), eicosane (C20H42), heneicosane (C21H44), docosane (C22H46), tricosane (C23H48) and tetracosane (C24H50) is shown in (Figure 6 The results of the study reveals that these fraction of oil sludge were properly degraded more than >88% in all treatment LIBeM as compared to natural attenuation. It was found that the long chain alkanes were completely degraded after 56 days of incubations except for tricosane were degraded to 88% in LIBeM-POW. The highest degradation of n-alkanes can be observed in the following range of LIBeM-POW>LIBeM-CAP>LIBeM-LIQ> NA with each treatment 3.3, 3.2 and 3.1-fold higher with NA. According to Tebyanian et al., [23], many organisms were found to grow on or can easily metabolically oxidize alkanes. In other similar study, the degradation of long chain alkane’s hydrocarbons was observed higher in bioaugmentation of mixed Acremonium Sp. and B. subtilis which significantly promoted degradation for all hydrocarbon fraction with >95% respectively. This study proved that bioaugmentation of LIBeM in oil sludge contaminated soil which consists of consortia strains (C. tropicalis-RETL-Cr1+ C. violaceum-MAB-Cr1 + P. aeruginosa- BAS-Cr1) have greater degradation capability to degrade aliphatic compounds with almost complete degradation (88%-99%) as compared to NA ( 30-56%) capability.

3.5 Degradation of polycyclic aromatic hydrocarbons (PAHs) by LIBeM-LIQ, LIBeM-POW, LIBeM- CAP and NA

Figure 7 showed the degradation of polyromatic hydrocarbons (PAHs) by LIBeM-LIQ, LIBeM-POW and LIBeM-CAP at 20% (v/v) of oil sludge study. Based on the result obtained, it was clearly showed that the selected of PAHs compound degraded was highest in LIBeMPOW with; Acenaphthene (83.9%) >Pyrene (81.6%)> >Anthracene (79%)> Naphthalene (73.4%) Benzo [b] Fluoranthene (60.5%)> Flourene (30.2%). On the other hand, LIBeM-CAP and LIBeM-LIQ showed moderate degradation of PAHs fraction with 30%-80%.

Natural attenuation treatment had the least biodegradation of PAHs hydrocarbon fraction (28% - 57%) throughout 56 days periods. It was observed that compound naphthalene achieved the maximum degradation of 80% after 56 days of incubation. Flourene and anthracene recorded the lowest degradation in LIBeM-CAP and LIBeM-LIQ with below than 35% respectively. Considering the above results mentioned, it can be concluded that the quick decomposition of 2 benzene rings of PAHs (naphthalene and acenapthalene) occur rapidly after final day of experiment. Hence it can be presumed that the LIBeM consortia added into the oil-contaminated soil were capable of biodegradation of PAHs compound in the soil.

3.6 Environmental parameters influencing biodegradation of oil sludge contaminated soil by LIBeM-LIQ, LIBeM-POW and LIBeM-CAP

There are three important environmental parameters need to be monitored for successful bioaugmentation namely biomass concentration, pH, and moisture content during 56 days treatments. Based on Figure 8 (a), it can be observed that the number of microbial cells in soil inoculated with consortia LIBeM using different delivery techniques were varied as a function of times in ASP-bioreactor system. The data presented showed that microbial cell counts of consortia LIBeM was higher in augmented soil with 2.3 fold as compared to natural attenuation. In particular, LIBeM-POW showed the highest viable cell at week 1 with 5.0 x 107 CFU/mL followed by LIBeM-LIQ with 4.0 x 107 CFU/mL and LIBeM-CAP with 2.0 x 107 g-1 CFU/mL at week 4 and 7 of treatment. The highest growth of LIBeM in ASPbioreactor system was significant with reduction of TPH in the soil through bioaugmented treatment. At week 1 and 7, microbial growth peaked of LIBeM-POW and LIBeM-CAP reached a maximum count. During this time, the TPH was also significantly reduced by 30.4% (week 1) and 68.8% (week 7) respectively as previously shown in Figure 4 (a) & (b).

The highest TPH reduction of oil sludge and increase in microbial population during experiment were occurred when the combination of indigenous and exogenous bacteria were employed. The highest growth rate of LBeM-LIQ, LIBeM-POW and LIBeM-CAP was related to the combination of three consortia C. tropicalis-RETL-Cr1+ C. violaceum-MAB-Cr1 + P. aeruginosa-BAS-Cr1 (RETL-Cr1+ MABCr1+ BAS-Cr1) thus resulted in the compatibility of the indigenous and exogenous bacteria for hydrocarbon degradation. This proved that applied augmented LIBeM showed capacity of tolerance and growth in oil sludge. This result agreed with the study of [24], who reported that the addition of augmented strains together with exogenous bacteria had positive impact on oil sludge biodegradation. As reported by Vanessa et al., [25] in context of hydrocarbon contaminated soil, the microorganism’s survival after inoculation and the content diversity autochthones of microbial communities are important factors that affect the biodegradation contaminant rate.

Figure 8 (b) shows the profile of soil pH treated by LIBeM-LIQ, LIBeM-POW, LIBeM-CAP and natural attenuation during 56 days treatment period. The results show that the pH profile of soil was recorded in range 5.15 to 7.93. Soil treated with LIBeM-LIQ showed the highest pH in week 7 with 7.93. The results also demonstrated the pH profile was observed varied along the bioremediation process. The decrease in pH value can be due to local decomposition of organic residue to acid or CO2 evolution, while the increase in the pH value may be a result of bicarbonate accumulation during biodegradation of petroleum compounds by microorganisms.

However, it is important to note that pH in soil by treated LIBeM were in the range for suitable biodegradation process. It was evident the level of pH in the soil had a significant effect on the rate of degradation. The optimum pH was found to be at 7.0 for soil treated with LIBeM. On the other hand, natural attenuation showed pH slightly acidic in average of 5. The extremes pH in natural attenuation shown to have a negative influence on the ability of microbial to degrade hydrocarbon population as experienced by [26,27]. As reported in previous research, microorganisms will thrive best in pH range from 6-8 [28]. When pH rose up to 8.5, the rates of biodegradation dropped significantly.

Figure 8 (c) shows the various profile of soil moisture content (%) during 56 days of experiment. It can be observed that the initial moisture content in soil was range from 19.04% - 23.3%. Along the incubation periods, the soil moisture content data recorded was increase and decrease due to air weathering and daily temperature during the remediation process. The moisture content of LIBeMLIQ was observed in range of (16%-24%) while LIBeM-POW was (20-27%), LIBeM-CAP (19-25%) and natural attenuation with 13- 23%. According to JRB Associates, [29]), biodegradation of oil in soil requires water for microbial growth and diffusion of nutrients and by product during the breakdown process. Arora et al., [30] reported that extreme wet or dry soils markedly reduce biodegradation rates. It can be concluded that soil moisture content recorded in treatment by LIBeM was suitable condition for biodegradation. Regardless the natural attenuation the low moisture content observed weekly was significant with low degradation of oil sludge in soil. Therefore control of soil moisture content can be practiced to optimize degradative process, and this it may achieved by several means such as soil additives, regular watering and other possible techniques [31].

4. Conclusion and Recommendation

Novelty of this developed technology on microbial formulation of LIBeM in liquid (LIBeM-LIQ), powder (LIBeM-POW) and capsule (LIBeM-CAP) in degrading oil sludge contaminated soil at high concentration level (20% v/v) was preformed based on technical procedures protocols (TP) as mentioned in this study.. The comparison between technical procedures protocol (TPP) of LIBeM-LIQ and LIBeM-POW together with LIBeM-CAP are also described. In context of bioremediation of oil sludge, the successful of bioremediation is mainly focused on the ability and efficiency of the strains used to degrade high percentage of oil subjected to short times taken. This marked by 3.5-fold, 3.3-fold and 1.5-fold higher of LIBEMPOW, LIBeM-CAP, LIBeM-LIQ than NA. Therefore treatment using LIBeM-POW is the most utter strategies in order to achieve the great removal of TPH (92%) degradation in soil with a short time needed. LIBeM-POW also is known to well adapt for land, water and hard surface. This microbial formulation is easy to use and handle with non-toxic, non-corrosive and is biodegradable with eco-friendly user and to be used as a green technology in treating oil sludge in oil and gas industries.

Competing Interests

The authors declare that they have no competing interests.

Acknowledgments

We are indebted to Department of Environment (DOE) Malaysia and Labuan Shipyard & Engineering Sdn. Bhd. for granting us permission to use and treat the oil sludge for this research.