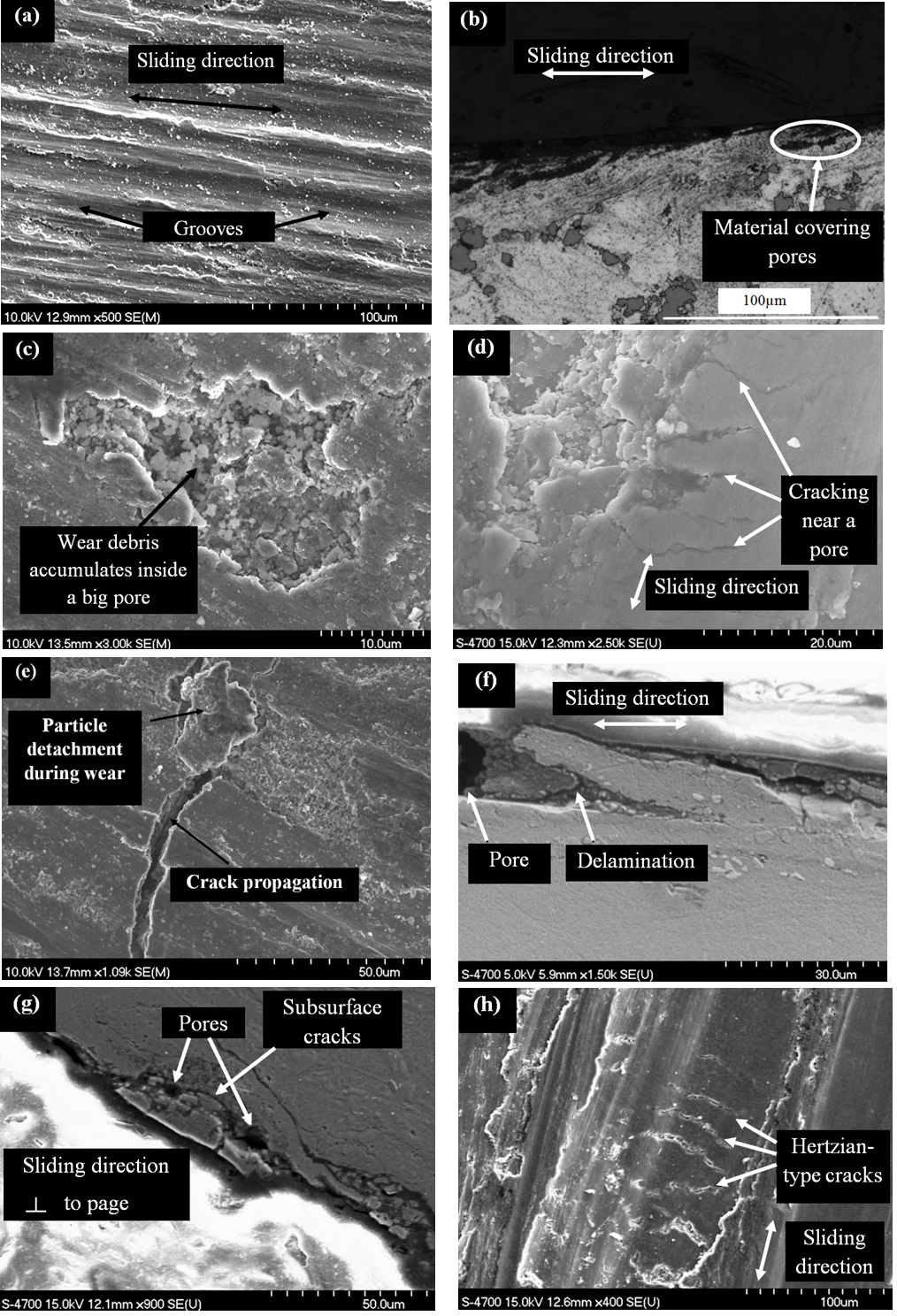

Figure 8: SEM micrograph of aluminum alloy,

(a) formation of grooves due to ploughing,

(b) optical micrograph of the cross-section of wear track shows pore covering by deformed material,

(c) entrapments of wear debris inside a pore,

(d) crack initiation near a pore,

(e) crack propagation,

(f) cross section of the wear track illustrating delamination,

(g) cross section of the wear track showing the propagation of sub-surface crack due to the presence of porosity and

(h) Hertzian-type cracks developed due to surface tensile stress.

(a) formation of grooves due to ploughing,

(b) optical micrograph of the cross-section of wear track shows pore covering by deformed material,

(c) entrapments of wear debris inside a pore,

(d) crack initiation near a pore,

(e) crack propagation,

(f) cross section of the wear track illustrating delamination,

(g) cross section of the wear track showing the propagation of sub-surface crack due to the presence of porosity and

(h) Hertzian-type cracks developed due to surface tensile stress.